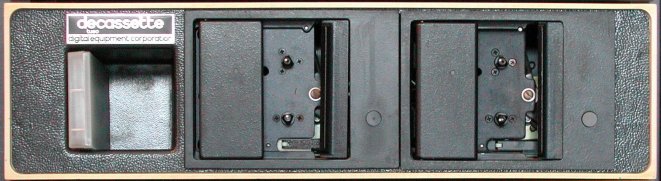

| TU60 tape drive and controller |

| Back to top |

During a write operation, 8-bit data bytes are parallel transferred from the interface to the TU60, phase encoded, and

serially recorded on the tape. Except for the tape length, there is no maximum limit to the number of bytes that may be grouped

into a data block. However, it is not possible to replace an individual block on a recorded tape. |

| ||||||||||||||||||||||||||||||||||||

| Back to top |

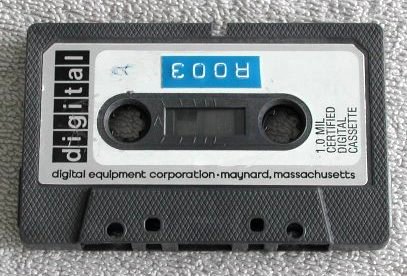

It is extremely important that only DEC, 100% certified, Digital Tape Cassettes are used on the TU60 tape drives. The

"heavy base" tape in this cassette was specifically chosen to be compatible with the high drive tensions of the TU60.

In addition, the head pressure pad material of the cassette has been carefully selected to allow proper take stacking.

For optimal operational characteristics, the dynamics of each tape drive require the use of only DEC cassettes.

It is extremely important that only DEC, 100% certified, Digital Tape Cassettes are used on the TU60 tape drives. The

"heavy base" tape in this cassette was specifically chosen to be compatible with the high drive tensions of the TU60.

In addition, the head pressure pad material of the cassette has been carefully selected to allow proper take stacking.

For optimal operational characteristics, the dynamics of each tape drive require the use of only DEC cassettes.Do not attempt to use an audio cassette on the TU60 tape drives.

Since the tape in an audio cassette is not designed to tolerate the high drive tensions of the TU60, use of this type

cassette will result in extremely rapid deterioration of the tape and subsequent failure of the drive due to excessive

tape oxide deposits on the read/write head and tape guides.

The DEC cassette is relatively more expensive than an audio cassette. The lower "high frequency roll-off" of the digital

tape also makes it a poor substitute for audio equipment. In addition, the coefficient of friction of the DEC cassette

tape does not allow tape motion by capstan and pinch rollers.

In short, the TU60 DECassette Tape Transport and the DEC, 100% certified, Digital Cassette are designed to be used together.

| The figure shows a typical TU60 data tape format. | ||||||||||||||

| Back to top |

Care of tape cassettes

Just as with diskettes, disks and other storage media there are some guide lines of use.

Loading and unloading the DECassette

If you load a new cassette (or a cassette just shipped or accidentally dropped), load the cassette on a drive and perform a rewind

operation. Then remove the cassette, turn it over, and perform an other rewind operation. This is done to pack the tape neatly

in the cassette and also to place the full tape reel at the proper operating tension.

A cassette may be loaded on the drive with the drive locking bar either opened or closed. However, it is easier to load a

cassette with the bar opened. Do the following steps to load a cassette.

The write protect tab is located on the cassette top right,

when viewed with the label side up. To inhibit a write operation, fold this tab back to open the cassette recess. To allow a write

operation, return the write protect tab to close the recess hole.

The write protect tab is located on the cassette top right,

when viewed with the label side up. To inhibit a write operation, fold this tab back to open the cassette recess. To allow a write

operation, return the write protect tab to close the recess hole.

Cleaning the TU60 DECassette Tape Drive

DIGITAL describes a preventive maintenance schedule in the maintenance manual which is based on a 4-hour use per day.

I do not think you run the unit that often as a hobbyist, but here are some useful tips.

| Back to top |

more to be added soon ...

| Back to top |

| You can toggle in the small program on the left side. The program starts at address 000200, and reads the switch setting of the Switch Register to set the tape motion. The switch settings are listed in the table at the right. |

|

The MAINDEC diagnostic programs use the following Switch Register settings.

SW 15=1 (100000) halt on error

SW 14=1 (040000) loop on test

SW 13=1 (020000) inhibit error reports

SW 10=1 (002000) ring bell on error

SW 09=1 (001000) loop on error

SW 08=1 (000400) do not change drive

SW 07=1 (000200) pause 200 ms

| Back to top |